- High-grade steel, aluminum, and custom metal alloys enhance strength, corrosion resistance, and longevity.

- Principles like load path analysis, wind and seismic resistance, and fatigue mechanics ensure reliability in diverse environments.

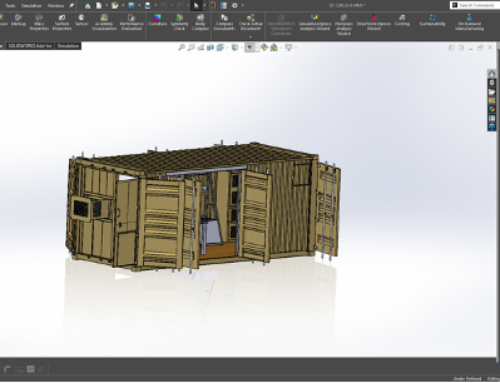

- CAD, modular construction, and rigorous quality assurance guarantee consistency, efficiency, and compliance with safety standards.

Relocatable structures have emerged as game-changers in the dynamic construction and design landscape, offering adaptability, efficiency, and cost savings. These structures are designed to be versatile, durable, and stable, even in the most demanding environments.

Let’s explore the scientific and engineering principles that make relocatable structures a reliable and long-lasting solution.

Powering Durability with Material Science

The materials used in relocatable structures influence their longevity and performance. Manufacturers like the SESOLINC Group prioritize high-grade steel, aluminum, and metal alloys due to their unique properties:

Steel

Steel is an ideal material for relocatable structures because of its strength and resistance to deformation. Its high tensile strength allows it to withstand heavy loads and resist external forces like wind, rain, and seismic activity. Additionally, galvanized or weathering steel ensures protection against corrosion, extending the structure’s durability.

Aluminum

Lightweight yet robust, aluminum is perfect for applications requiring portability. Its natural resistance to corrosion and recyclability make it a sustainable choice, especially in humid or coastal environments.

Metal Alloys

Custom metal alloys are often used to achieve specific performance goals, such as increased heat resistance or improved weldability, ensuring the structures are suitable for various environmental conditions.

Steel and aluminum are popular choices due to their high strength-to-weight ratio, allowing for robust yet lightweight structures.

Structural Engineering Principles for Strength and Stability

Relocatable structures, while designed for mobility, must adhere to rigorous structural engineering principles to ensure strength, stability, and longevity. These principles, combined with careful material selection and meticulous fabrication, are crucial to withstand the stress of transportation, repeated assembly and disassembly, and diverse environmental conditions.

The following design principles are critical:

Load Path and Stress Distribution

A fundamental principle in structural engineering is understanding the load path—how forces travel through the structure to the foundation. It includes dead loads like the structure’s own weight, live loads like occupants and furniture, and environmental loads like wind and snow. This is particularly critical in relocatable structures, as the load path may change during relocation and reassembly.

The design must also ensure loads are efficiently transferred through the structural members (walls, beams, columns, and roof) to the foundation. This often involves strategically placing reinforcement, strong connections between modular units, and load-bearing elements to handle tension and compression forces. Additionally, minimizing stress concentrations is key to preventing structural failure. This is achieved through proper geometry of structural members, avoiding sharp corners where stress can build up, and using appropriate connection details that distribute loads evenly.

Wind and Seismic Resistance

Relocatable structures are often deployed in diverse environments, which demand robust resistance to lateral forces like wind and seismic activity. Engineers conduct detailed wind load analysis, considering factors like wind speed, exposure category, and the structure’s shape and height. This decides wind-resistant features such as aerodynamic profiles, shear walls, and roof tie-downs.

In earthquake-prone regions, relocatable structures incorporate features like base isolation systems, flexible connections, and energy dissipation mechanisms to minimize damage during seismic events.

Connections and Joints

Connections are critical points in any structure, and even more so in relocatable structures where they are repeatedly stressed during assembly and disassembly. They must be designed to transfer the anticipated loads without failure. Welding, bolting, and specialized connectors are commonly used, depending on the materials, the magnitude of the loads, and the need for disassembly. Protecting connections from corrosion is also vital for long-term durability, especially in harsh environments. This often involves using corrosion-resistant materials, protective coatings, and proper detailing to prevent water accumulation.

Fatigue and Fracture Mechanics

The transportable nature of relocatable structures exposes them to repeated loading and unloading cycles, increasing the risk of fatigue cracking and eventual failure.

- Fatigue Life Prediction: Engineers use fatigue analysis techniques to accurately predict the lifespan of critical structural components, ensuring they can withstand the anticipated number of relocation cycles without compromising safety.

- Fracture Mechanics: By studying how cracks initiate and propagate in materials, engineers apply fracture mechanics principles to design structures that can tolerate minor flaws, reducing the likelihood of catastrophic failures and enhancing durability.

Bringing Precision with Prefabrication

A defining feature of relocatable structures is their advanced prefabrication process. This approach guarantees exceptional precision and rigorous quality control, both of which are critical for ensuring long-term durability and reliability.

- Computer-Aided Design (CAD): CAD software allows engineers to create detailed and accurate blueprints, minimizing errors during manufacturing.

- Modular Construction: Prefabricated components are produced in controlled environments, reducing exposure to weather-related wear and ensuring consistent quality. These modules are then transported and assembled on-site, enabling faster installation and reduced labor costs.

- Standardization and Customization: While standard designs ensure cost-effectiveness, manufacturers also offer customized solutions tailored to specific needs. This balance between standardization and customization allows the structures to meet diverse application requirements without compromising quality.

Testing and Quality Assurance

True strength and stability extend beyond theoretical calculations and meticulous design, and that’s why rigorous testing and quality assurance are deeply ingrained in the manufacturing process. This ensures that every relocatable structure produced meets the highest standards of performance and longevity.

Load Testing: Subjecting the structure to specific loads such as weights, forces, or pressures to verify its strength and stability. The goal is to ensure the structure can safely handle the loads it is designed for, including both everyday usage (like occupants and furniture) and extreme conditions (like storms or heavy equipment), without deforming or failing.

Weather Simulation: Tests how structures and materials perform under various environmental conditions, using techniques like wind tunnel tests to simulate high winds and thermal chambers to replicate extreme temperatures. These simulations help identify potential weaknesses in the design, ensuring the structure remains resilient over time and across diverse climates.

Compliance Checks: Meticulous product reviews to ensure they meet all applicable building codes, safety standards, and industry certifications. This step is critical for ensuring regulatory compliance and providing customers with confidence in the safety, reliability, and legal approval of the structures.

There are numerous other advanced concepts ranging from thermal dynamics to innovative material engineering that play a vital role in building robust relocatable structures. The SESOLINC Group can help you dive deeper into the intricate aspects. Our experts will work with you to design and build a solution that meets your specific requirements while ensuring strength, stability, and long-lasting performance. Contact us today for more details.