“MEASURE TWICE, CUT ONCE”!! The heart of every successful design/manufacturing project is solid engineering. SESOLINC Engineers play a vital role in bringing concepts and ideas into reality. making sure that structures are safe, efficient, and visually appealing. This detailed process involves planning and constant collaboration among the members of Product Development.

The Role of Engineers in Design

SESOLINC’s Engineering Staff thoroughly understands the materials science and structural analysis required to create functional and safe designs. They ensure that every design element works harmoniously, meets regulatory requirements, and withstands various environmental stresses.

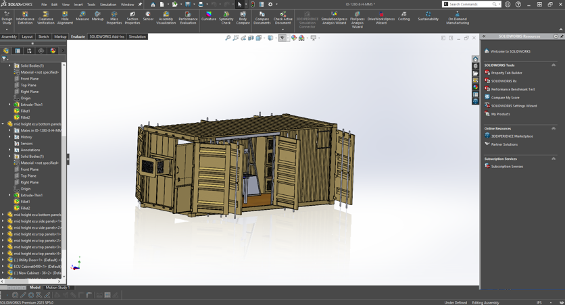

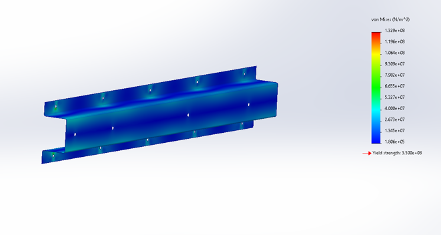

Finite Element Analysis [FEA] allows for detailed modeling to stress and strength test components and end products prior to construction. See the link for more detailed description.

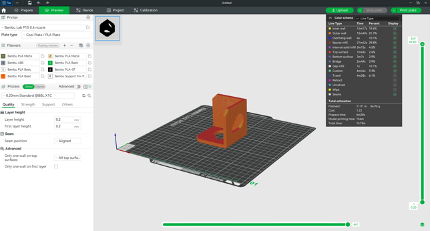

By integrating advanced drawing/modeling/FEA technologies and analytical methods, Engineering is able to physically and virtually prototype products for efficiency and rapidity of manufacture. Prototyping and analysis of designs provides the ability to perform simulations on those designs to confirm the stress, strain, and factor of safety characteristics.

Designs can be prototyped using additive manufacturing, which is cost and time effective for smaller products. Larger products can be prototyped using our Computer Numerical Control [CNC] equipment, ie.: laser, plasma table as well as lineup of CNC press brake, shears, and tubing bender. The CNC methods are effective with larger products or products which may need to be prototyped in steel or other metals.

Properly designed and engineered projects optimize the efficient use of resources and minimize waste in the construction process.

Integrating Engineering Support in the Design Process

Engineering support encompasses the entire design/product life cycle and includes various services, from design and prototyping to testing, manufacturing, and maintenance.

Initial Consultation and Needs Assessment

The first step in any engineering design project is understanding the client’s needs and objectives. This involves detailed consultations to gather information about the structure’s intended use, site conditions, budget constraints, and any specific requirements. Engineers use this information to clearly understand the project scope and identify potential challenges early on.

Conceptual Design and Feasibility Analysis

Once the initial consultation is complete, engineers move on to the conceptual design phase. This involves creating preliminary sketches and models to explore different design options. During this phase, engineers also conduct feasibility studies to evaluate the practicality of each design, considering factors like structural integrity, cost, and sustainability.

Detailed Design and Technical Drawings

Engineers create detailed technical drawings and specifications after selecting the most appropriate design concept. These documents serve as a blueprint for the construction process, providing precise measurements, materials lists, and assembly instructions. The detailed design work makes sure that every component of the structure is accounted for and that the final product meets all necessary performance and safety standards.

Engineering Support During Construction

Engineering support doesn’t end with the design phase. During the construction phase, engineers play a vital role in ensuring that the project is executed according to plan. This involves regular site visits, inspections, and adjustments to address any unforeseen issues that may arise. Engineers also maintain close oversight throughout the construction process to check if the final structure meets the highest quality and safety standards.

The Importance of Innovation in Engineering Design

Innovation is a key driver of progress in engineering design. Continuously seeking out new materials, methodologies, and technologies upgrades products and services across the industry. This commitment allows for the delivery of effective solutions:

Increased Safety Measures

Engineers can design structures that are more resilient to natural disasters, accidents, and other potential hazards by incorporating the latest advancements in materials and construction techniques. This focus on safety helps protect lives while reducing long-term maintenance costs and increasing the lifespan of the structures.

What the Future Holds

The future of engineering in design looks increasingly promising as technology evolves. New possibilities are opening up for creating more sustainable, sophisticated, and innovative structures:

Digital Modeling and Simulation

Increasingly detailed and accurate digital modeling programs improve efficiency of the design process while leading to better product/client outcomes. They allow for more accurate and detailed analysis of design concepts, enabling engineers to optimize performance and identify potential issues before construction begins.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are also beginning to play a role in engineering design. The former can be used to optimize the layout of a structure under various conditions, while the latter can analyze vast amounts of data to identify patterns and insights that can inform design decisions.

Looking to transform your ideas into innovative designs? Look no further than our team at The SESOLINC Group.Contact us today to explore how our engineering expertise can bring your vision to life with precision, efficiency, and sustainability.